Thermoplastics

Thermoplastics are the most widely used materials in 3D printing because of their ability to soften when heated and solidify when cooled. This characteristic allows for layer-by-layer deposition, which is fundamental in additive manufacturing processes.

We print with various thermoplastic filaments, such as PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), PETG (Polyethylene Terephthalate Glycol), TPU (Thermoplastic Polyurethane) and PA (Polyamide Nylon).

Each of these materials has its own unique properties, making them suitable for different applications.

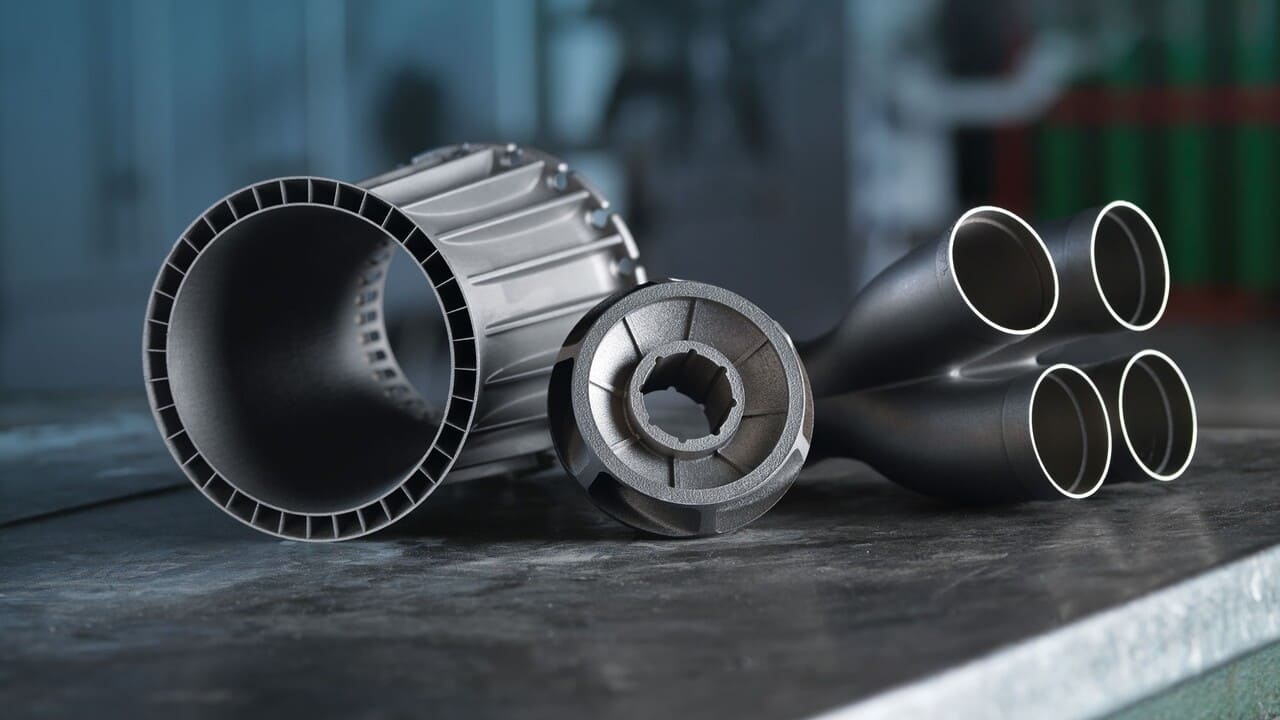

Metals & Alloys

Unlike traditional subtractive manufacturing processes where material is removed from a metal block, metal 3D printing uses high-powered laser to selectively melt and fuse metal powder, layer by layer, to create the final object, making it possible to create intricate designs and structures.

Common materials for metal 3D printing include various alloys of stainless steel, titanium, and aluminum.

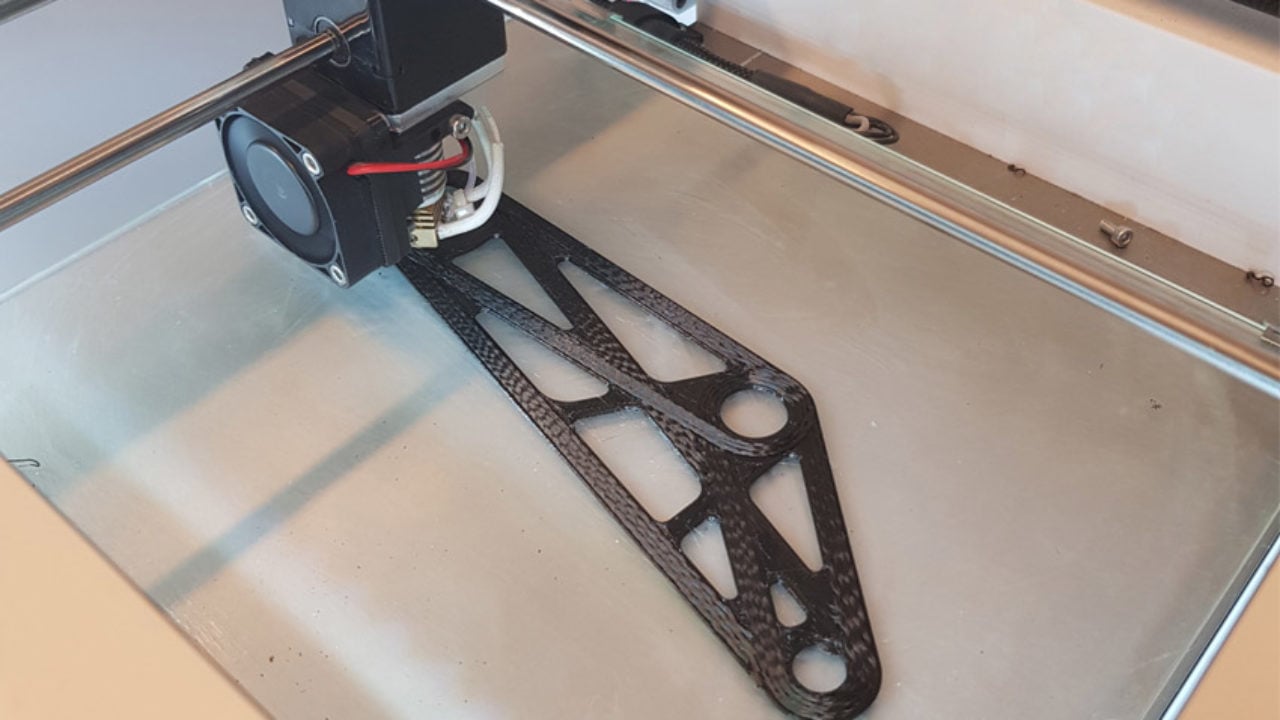

Composites

Composites refer to materials composed of two or more different substances to create objects with enhanced or tailored properties. Combining the benefits of various materials allows for the creation of 3D-printed parts with improved strength, stiffness, weight reduction, and other characteristics.

We print with combination of thermoplastic polymer matrices with reinforcing materials like carbon fibers, glass fibers, or aramid fibers.