DfAM (Design for Additive Manufacturing)

DfAM harnesses the true potential of additive manufacturing and takes your product designs to unprecedented heights. Our services are here to help you optimize your concepts for maximum performance, efficiency, and creativity.

Complex Designs

Additive manufacturing allows designers and engineers to access a vast new design space. We can create parts that are intricate, inspired by nature, and optimized for their precise application, not for manufacturability, resulting in parts that perform better than their traditionally manufactured counterparts.

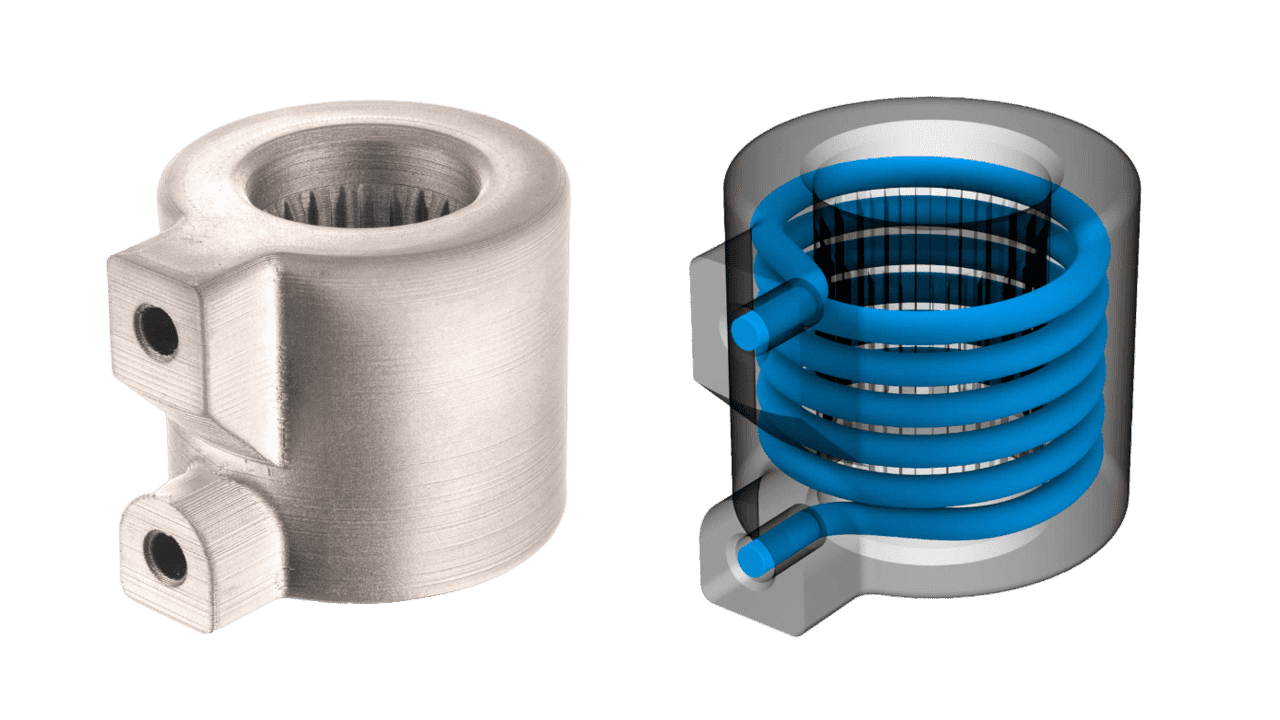

Internal Features and Channels

We use the open internal design liberty of AM to create parts with internal features - like conformal cooling channels, and fins - that would be impossible for conventional manufacturing approaches.

Fine Features

Machining very small features is notoriously difficult because parts tend to chatter unless they are supported during cutting. Our designers can incorporate fine features into the part design for AM which would be too time-consuming and expensive to justify creating via conventional processes.

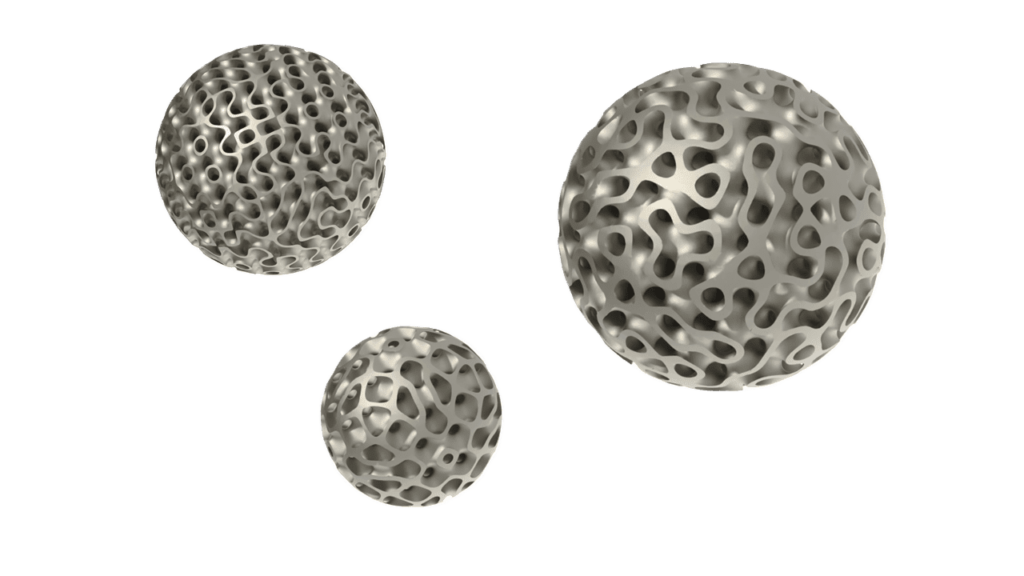

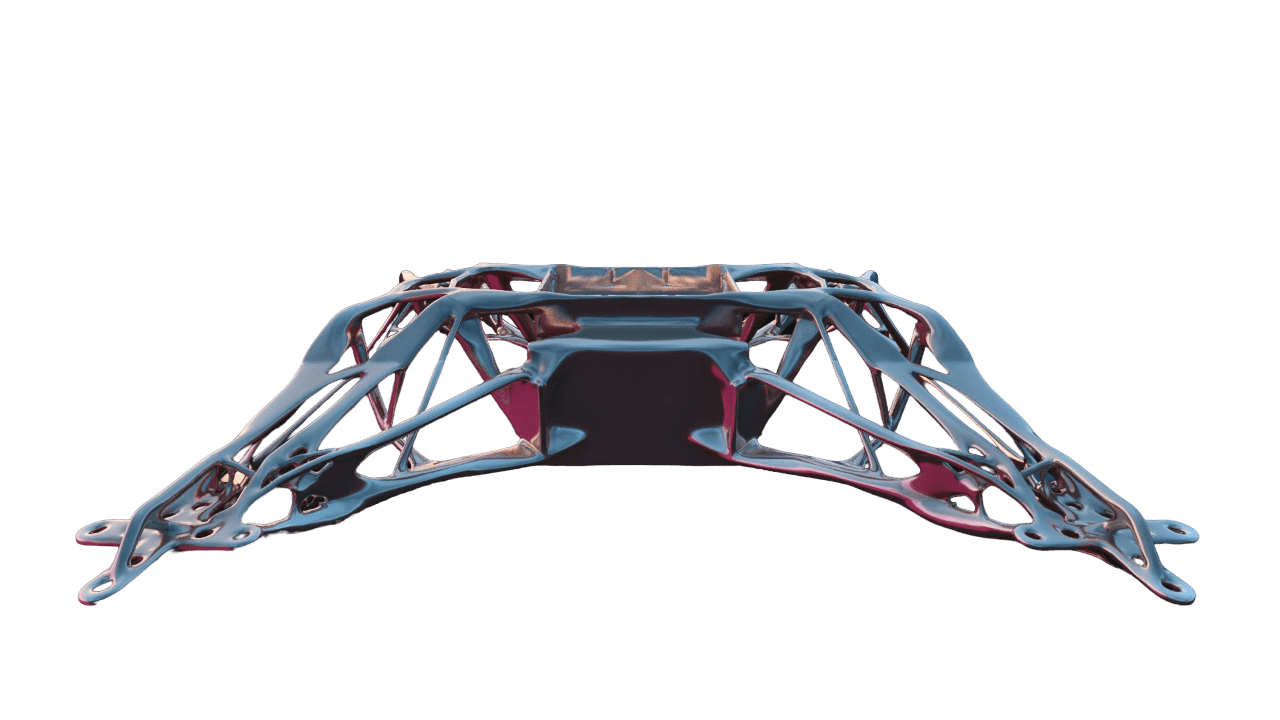

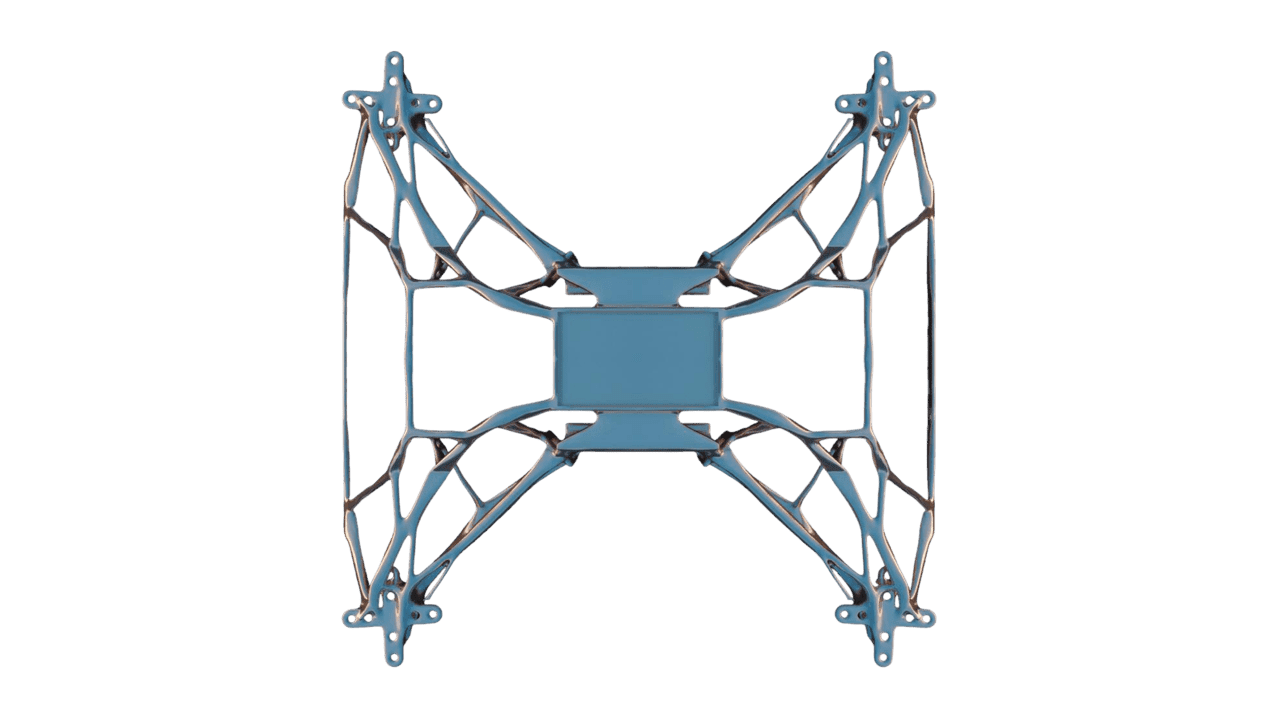

Lattice Structures

Our team specialises in dealing with formula-based self-supporting lattice structures that have high accuracy and efficiency. We replace solid sections of components with these lighter structures, while still maintaining the required strength and stiffness. We are using these structures to push the boundaries of design and set new standards for future design.

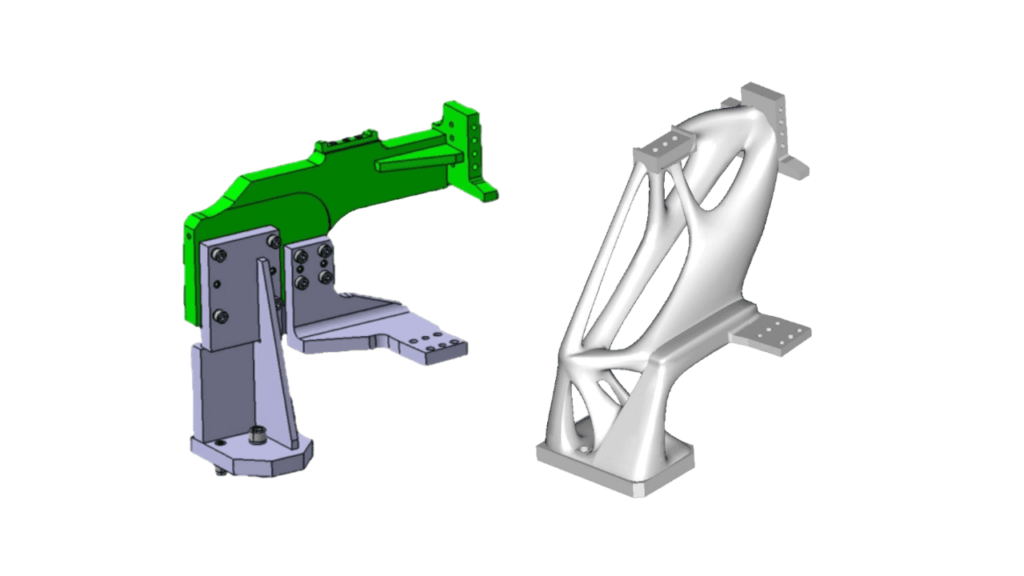

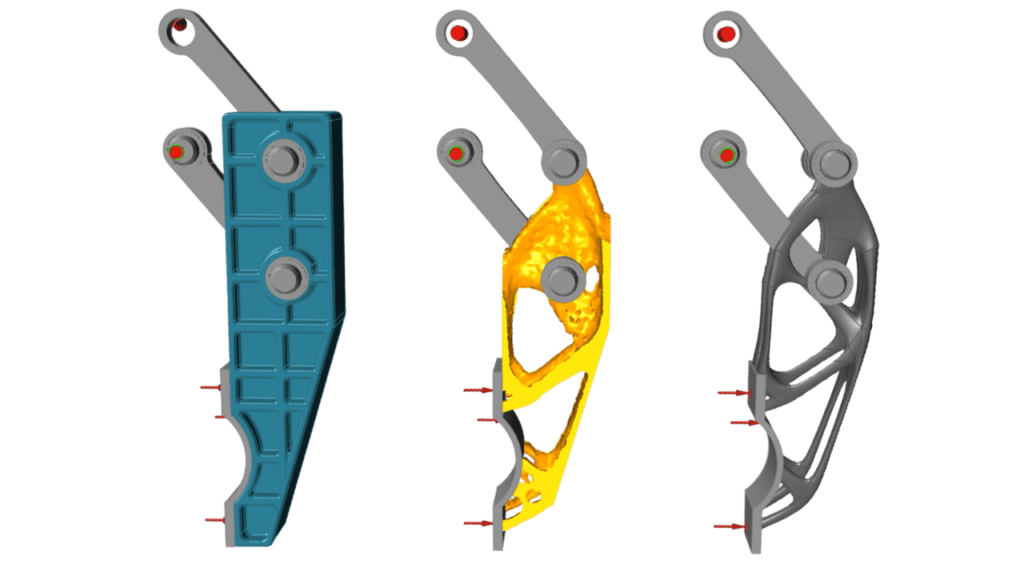

Topology Optimization

We specialise in Topology optimization (TO), an algorithmic model that maximizes the performance and efficiency of your design by removing redundant material from areas that do not need to carry significant loads. Our TO designs are a perfect match for AM processes to easily produce complex shapes without additional costs.

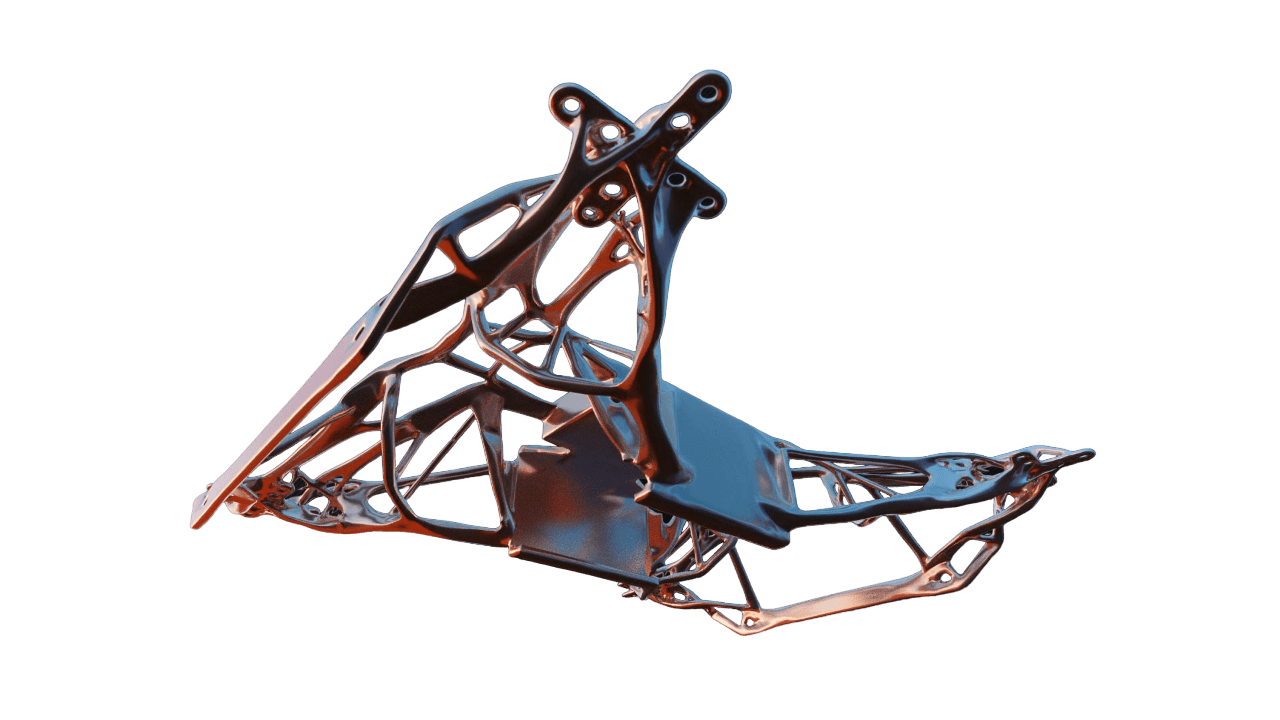

Functional Generative Design

We use functional Generative design, an iterative design exploration that uses an AI driven program to generate a range of design solutions. By modifying the design parameters in an increasingly refined feedback loop, our engineers can quickly assess a range of design outputs that are highly optimized for performance and manufacturing cost.

Assembly Consolidation

Additive nature of 3D printing gives our designers the design freedom to combine multiple components or subassemblies into a single, more integrated, and efficient component. Our designs increase production efficiency significantly - manufacturing a single part via 3D printing is faster and cheaper than producing several different parts via traditional methods and fastening or welding them together.